Can Your Current Supplier Handle Your SMT PCB Assembly Requirements

2025-08-20

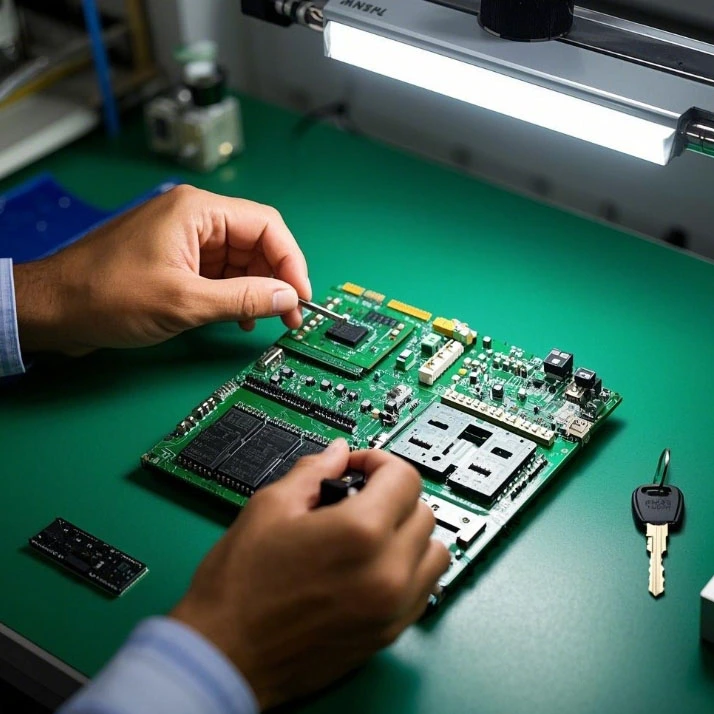

Is your electronics manufacturing being slowed down by a supplier who can't keep up? In today's fast-paced market, you need a partner that delivers precision, speed, and reliability. Many suppliers promise excellence but fall short on the technical capabilities and communication required for complex SMT assembly. This is where Greeting steps in, offering a superior PCB Assembly Service built to meet modern demands.

What Technical Capabilities Should You Demand

Not all suppliers are created equal. You need a partner with proven expertise and state-of-the-art equipment. At Greeting, our technical specifications are designed to handle your most challenging projects.

| Capability | Greeting's Standard |

|---|---|

| Smallest Component | 0201 (metric 0603), 0.3mm pitch BGA |

| Placement Accuracy | ±25μm @ 3σ (6 Sigma) |

| Maximum Board Size | 510mm x 460mm |

| SMT Placement Speed | 0.035 seconds per chip |

| SPI (Solder Paste Inspection) | Integrated 3D AOI |

Our process ensures quality at every stage:

-

Advanced SMT Lines: 8 high-speed placement machines for accurate component mounting.

-

Stringent Quality Control: Automated Optical Inspection (AOI) and X-Ray for hidden joint analysis.

-

Full Testing: In-circuit (ICT) and functional testing (FCT) guarantees performance.

PCB Assembly Service FAQ

What is your typical turnaround time for prototype orders?

Our standard turnaround for prototype PCB Assembly Service is 5-7 business days, with expedited options available to meet urgent project timelines without compromising on quality.

How do you handle component sourcing and avoid shortages?

Our PCB Assembly Service includes expert component sourcing. We leverage long-term relationships with major distributors and a global network to secure parts, manage risk, and prevent project delays.

Do you offer design for manufacturability (DFM) feedback?

Yes, a cornerstone of our PCB Assembly Service is a comprehensive DFM review. We analyze your design files pre-production to identify potential issues, suggest improvements for yield and reliability, and save you time and cost.

Why Settle for Less When You Can Have a True Partner

Don't let an underperforming supplier hold your innovation back. Greeting provides the technical expertise, transparent communication, and reliable execution your products deserve. Contact us today for a detailed consultation and see how our advanced PCB Assembly Service can become your competitive advantage.